Financial District

Manhattan, NY

Custom Steam

Condensate Return Unit

Project Overview

At 88 Pine Street, the existing condensate return system was undersized and overwhelmed. With two absorption chillers generating high volumes of high-temperature condensate, the building was experiencing backups, temperature compliance issues, and unreliable operation. Time was critical, as the facility needed a fast turnaround to avoid disruptions to chiller operation and potential violations of discharge regulations. The system also needed to handle a 150-foot horizontal run and a 10-foot vertical lift while staying within New York City code, which requires condensate to be cooled to below 140°F before sewer discharge.

System Challenges

The building’s two absorption chillers produced a combined condensate return demand of approximately 75 GPM, with return temperatures often exceeding 200°F. NYC sewer code restrictions required this to be cooled below 140°F before discharge. Additionally, the system needed to overcome 150 feet of horizontal piping and a 10-foot vertical lift, necessitating a discharge pressure of at least 30 PSI. Off-the-shelf options couldn’t meet these performance demands, prompting the need for a custom-engineered solution.

Solution

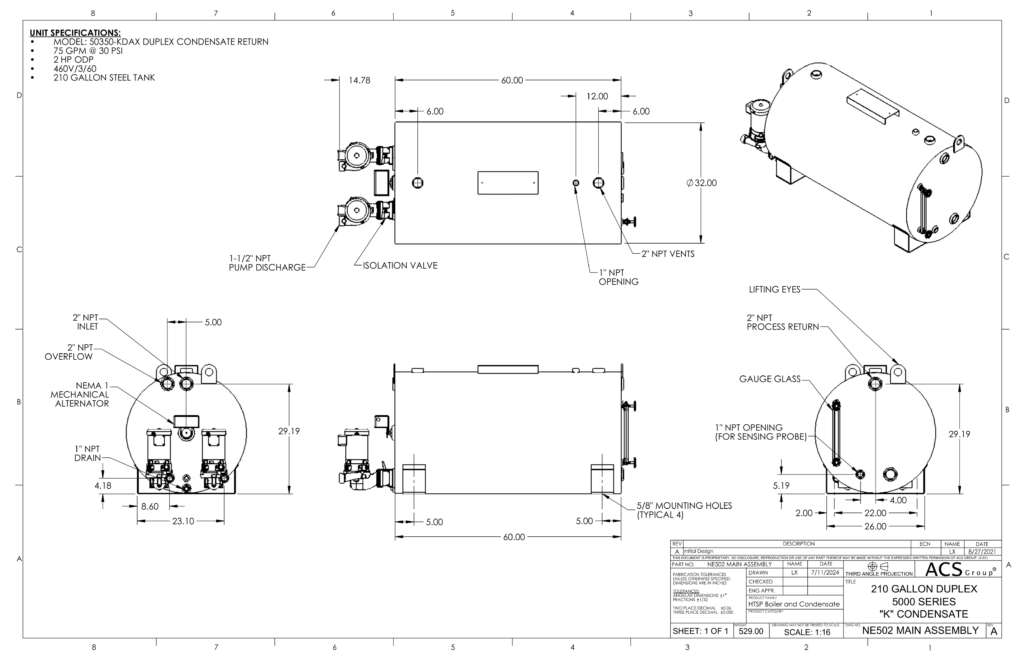

To meet these specific site requirements, Rathe Associates collaborated with Sterlco and the on-site engineer to provide a custom-built 50350-KDAX Duplex Condensate Return Unit. The customer needed a fast turnaround, and Sterlco delivered—one of their standout advantages is the ability to engineer and supply both standard and custom equipment with minimal lead times. Their speed and flexibility made them the ideal partner for this time-sensitive application.

The system was designed for 75 GPM at 30 PSI, with pumps rated for up to 210°F condensate and a 210-gallon steel tank (32 inches in diameter by 60 inches long). Additional features such as a mechanical alternator, gauge glass, isolation valves, and lifting eye bolts ensured the unit could reliably manage high-temperature flows while satisfying local code requirements.

Results

The new condensate return system eliminated the capacity bottleneck, ensured proper cooling of high-temperature condensate, and delivered consistent performance with built-in redundancy. With the proper tank size, flow rate, and pressure handling, the building now operates safely and efficiently while maintaining compliance with NYC DEP standards.